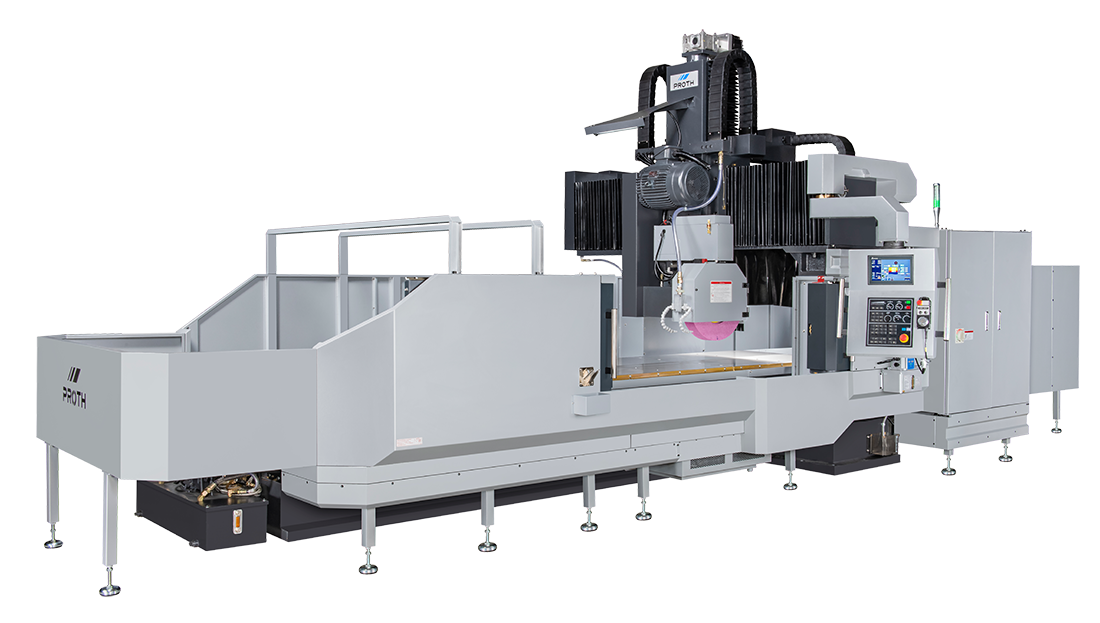

PSGP-1015CNC / PSGP-1020CNC / PSGP-1025CNC / PSGP-1030CNC / PSGP-1040CNC

- Home

- Products

- CNC SERIES

- PSGP-1015CNC / PSGP-1020CNC / PSGP-1025CNC / PSGP-1030CNC / PSGP-1040CNC

- Description

- Specification

- Optional

| Longitudinal Slideways | Cross Slideways | Longitudinal Movement | Cross Movement | Vertical Downfeed | Controller |

|---|---|---|---|---|---|

| Double Vee Ways | Flat-Dovetail Type Gibbed Ways | Hydraulic | FANUC Controlled System | FANUC Controlled System | FANUC |

- Straightness of table movement in longitudinal direction 0.02mm/m.

- Straightness of table movement in transverse direction 0.02mm/m.

- The surfaces of longitudinal table ways are all hand scraped to getting perfect contact pattern and to ensure very high accuracy.

- Longitudinal table ways are designed to have slide surfaces longer than that of the working surface and equal to the table length to keep the table free from torsion and deflection.

| SPECIFICATION / MODELS |

PSGP | ||||||

|---|---|---|---|---|---|---|---|

| 1015CNC | 1020CNC | 1025CNC | 1030CNC | 1040CNC | |||

| General Capacity | Max. travel (cross x longitudinal) | mm | 1200x1650 | 1200x2150 | 1200x2650 | 1200x3150 | 1200x4150 |

| Wheel bottom to table (Vertical Head) |

mm | 0-750 | |||||

| Spindle center height from table | mm | approx. 1100 | |||||

| Max. height from table top to bottom of standard wheel | mm | 845 | |||||

| Grinding surface of table | mm | 1000x1500 | 1000x2000 | 1000x2500 | 1000x3000 | 1000x4000 | |

| Longitudinal Movement | Hydraulic table speed | m/min | 2-25(1-25) | ||||

| Cross Movement | Clearance between the columns | mm | 1200 | ||||

| Intermittent cross feed-approx.(Electro-mechanical) | mm/feed | 0.1-35 | |||||

| Continuous cross feed-approx.(Electro-mechanical) | mm/min | 2000 | |||||

| Hand feed per revolution | mm | 5 | 10 | ||||

| Hand feed per division | mm | 0.02 | 0.05 | ||||

| Vertical Downfeed | Rapid traverse approx. | mm/min | 250 | ||||

| Hand feed per division MPG | mm | 0.001 | |||||

| Grinding Wheel | Dimension(O.D x W x I.D) | mm | 510x100x203.2 | ||||

| Spindle speed(50/60Hz) | r.p.m. | 1150 | |||||

| Motor | Horizontal head spindle motor | 11(15,18.5)kW/15(20,25)HP | |||||

| Vertical head spindle motor | 7.5kW/10HP | ||||||

| Hydraulic motor | 7.5kW/10HP | 11kW/15HP | |||||

| Weight | Net weight | kg | 10000 | 13500 | 17500 | 22000 | 36500 |

| Gross weight | kg | 13000 | 17000 | 21500 | 26500 | 41000 | |

| Machine Size | Dimension (L x W x H) | m | 5.1x4.6x3.9 | 6.2x4.6x3.9 | 7.3x4.6x3.9 | 8.4x4.6x3.9 | 11.2x4.6x3.9 |

| CNC Specification | Crossfeed rapid feedrate(approx.) | mm/min | 2000 | ||||

| Cross/Vertical infeed least input increment | mm | 0.001 | |||||

| Rapid vertical rate | mm/min | 500 | |||||

Notes:

- Since we subscribe to a process of continuous improvement for our products specifications are subject to change without notice.

- Machine appearance will change depending upon different optional equipment selected.

- Equipment marked with () is available at additional extra charge. Other special applications may be provided upon specific requests from customers. Please contact us for more details.

- Machines are shown with optional equipments.

Wheel Flange

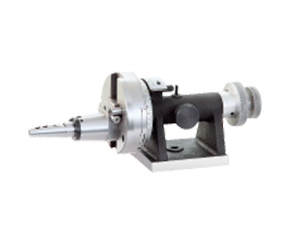

Radius and Angle Dresser

(PSGS)

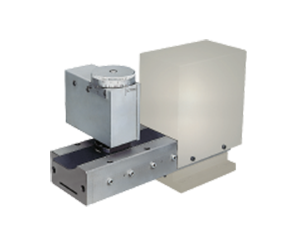

Parallel Dressing Attachment (Manual Type for PSGS) ※With The Exception of PSGS-1535M, 1545M, 2045M

Cross/Vertical Micrometer Attachment (PSGS-2550AH, 3060BH, 4080AHR)

Cooling System

Level Type Wheel Balancer

Electro Magnetic Chuck

Automatic Paper Serip Filter

Cooling System Magnetic Separator

Parallel Dressing Attachment (PSGO)

Dust-Suction Cooling System(PSGS)

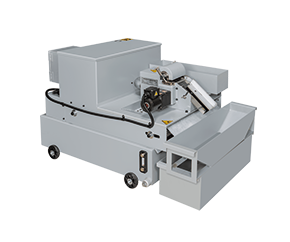

Auto-Parallel Dressing Attachment 2 Axes Full Auto (Electrical Cross+Step Control Down)

1.Window Type Splash Guard (PSGS) 2.Rear Side Coolant Baffle (PSGS)

Oil Temperature Control System

Oil Mist Collector